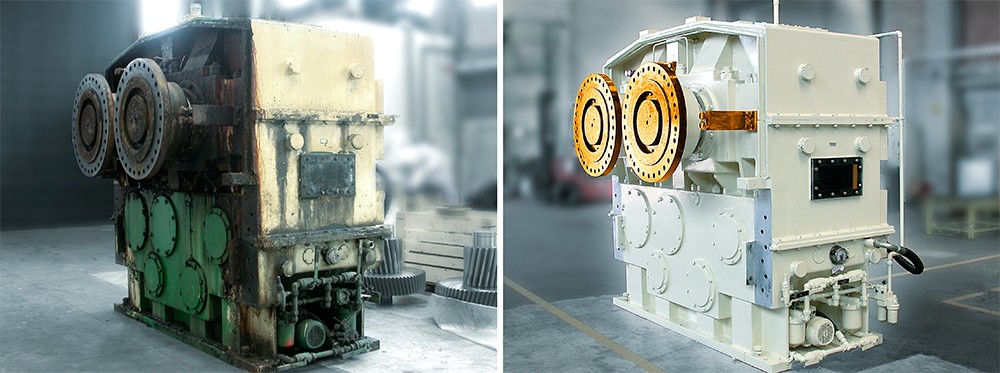

Overhaul and repair of gearboxes and gearmotors

Both standard and special gearboxes are fundamental parts of any industrial plant. It is therefore highly advisable to subject them periodically to a thorough overhaul and subsequent refurbishment, in order to restore their reliability and gradually reduced performance.

The revamping work we carry out on multi-brand gearboxes (as necessary also at your premises) involves the dismantling and inspection of potentially critical components such as gears, bearings, shafts and seals. At the same time, bearing seat measurements and geometric checks are made, while components intended for reuse (shafts and/or gears) undergo non-destructive testing.

Once the compromised parts have been identified, the gearbox is refurbished, all bearings and seals are replaced and the gears reworked or replaced. If necessary, the housings are also reworked and the inside of the case is repainted with oil-resistant paint.

Subsequent reassembly of the gearbox involves adjusting the axial and radial clearance for the operating bearing and checking the clearance and contact areas of the gears. All this is completed by painting the outside of the gearbox to renew its appearance.

The mechanical units reconditioned in this way are then tested for compliance at nominal speed, monitoring the increase in temperature and using a specific lubricant that is constantly filtered. Finally, vibration levels are measured and captured in an advanced manner.

It should also be pointed out that revamping, particularly when carried out on especially old gearboxes, often has the consequence of improving their original technical potential, since technological developments since the product was designed mean that performance can be upgraded, sometimes substantially.