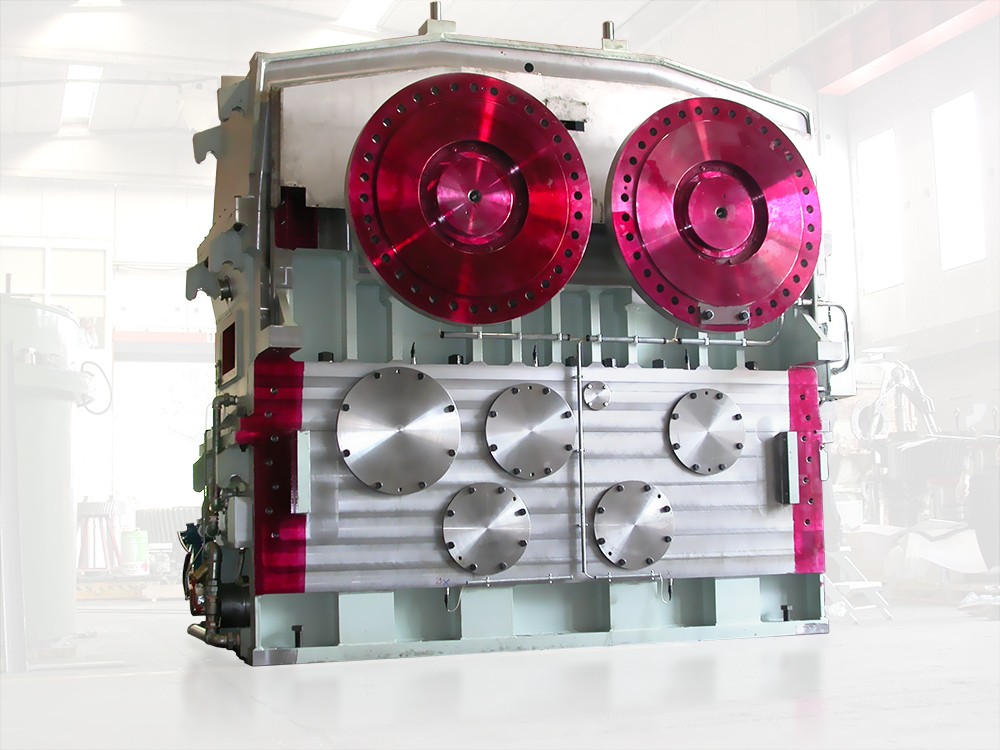

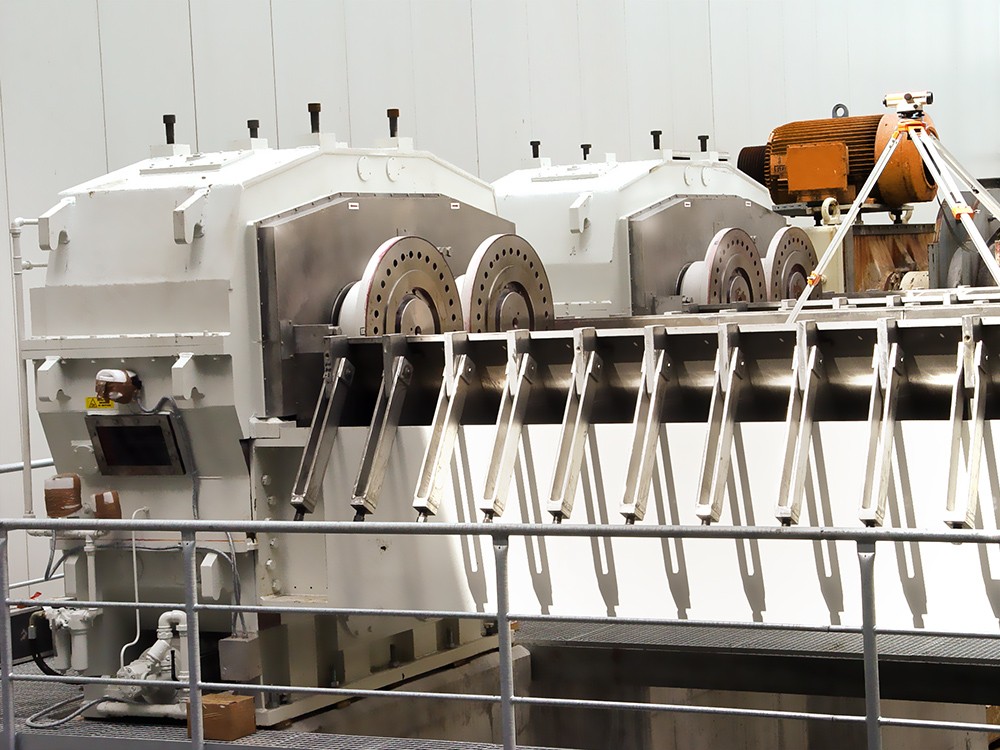

Parallel axes gearboxes for dewatering pressing of sugar beet pulp

GPS Engineering is particularly known worldwide for the manufacturing and designing of gearboxes and transmission gears for sugar factories. The gearboxes for pulp presses are among the most widely tested and boast more than 50 years of operation worldwide, with almost 1000 presses installed in the biggest sugar groups. Gearboxes for pulp presses are very highly reliable and are able to achieve high performances during their operating period, which depends on beets harvesting. GPS assures compliance with international standards, a scrupulous control during the whole manufacturing process, and a quick delivery for gearboxes and spare parts. In addition, GPS is able to manufacture perfectly interchangeable gearboxes to replace existing ones, even if these were originally manufactured by other suppliers.

Finally, it is possible to carry out complete revisions and to study focused uprating of existing gearboxes.

PB22, PB32, PB48, TECHNICAL DATA:

● Perfectly oil-proof steel case, consisting in steel structural work, welded, sandblasted, painted, subjected to stress relieving treatment

Wire welding with gas shielding.

● Main weldings checked with magnet-particle test.

● Inspection doors for endoscopic and visual checks.

● Primary make rolling bearings, optimised rolling elements profiles and materials.

● Gearing in casehardened and hardened steel with ground teeth profile.

● Class 6 gears in compliance with DIN 3962, or higher

● Slow shafts in alloy steel from tempering 39NiCrMo 3 tempered HB 240- 260 with optimum fatigue strength.

● Forced lubrication by means of control unit installed next to the gearbox, consisting in: gear motor pump, double filter with maintenance during operation, water/oil heat exchanger. Flow control instruments: pressure probe, temperature probe, flow switches in strategic points, electrical oil level control.

● Oil temperature thermoregulation: water/oil heat exchanger and oil heater.

● Completely wired systems with junction box for an easier on-site installation.

| PB22 | PB32 | PB48 | ||||

|

VERSION “ S “ |

VERSION “ SP “ |

VERSION “ S “ |

VERSION “ SP “ |

VERSION “ S “ |

VERSION “ SP “ |

|

| Rated inlet power approx. | 200 KW | 270 KW | 300 KW | 400 KW | 500 KW | 750 kW |

| Reduction ratio | 1 : 120 | 1 : 143 | 1 : 99 | 1 : 112 | 1 : 155 | 1 : 180 |

| Slow shaft speed – rpm | from 1 to 4 | from 1 to 4 | from 1 to 4 | from 1 to 4 | from 1 to 4 | from 1 to 4 |

| Fast shaft speed – rpm | 120 -> 480 | 140 -> 560 | 100 -> 400 | 110 -> 450 | 155 -> 620 | 180 -> 720 |

| Service factor AGMA | >1.4 | >1.6 | >1.4 | >1.6 | >1.4 | >1.7 |

| Rated torque at the outlet – Nm | 1.030.000 | 1.290.000 | 1.550.000 | 2.000.000 | 2.550.000 | 3.560.000 |

| Axial thrust on each shaft – N | 1.000.000 | 1.000.000 | 2.000.000 | 2.000.000 | 3.000.000 | 3.000.000 |

| Dimension – m | 2.5 x 1.8 x 2.5 H | 2.5 x 1.8 x 2.5 H | 3 x 2.1 x 2.8 H | 3 x 2.1 x 2.8 H | 3.5 x 2.4 x 3.6 H | 3.5 x 2.4 x 3.6 H |

| Gearbox weight – Kg | 20.000 | 22.000 | 31.000 | 36.000 | 48.000 | 56.000 |

GPS Engineering reserves the right to modify the characteristics of the products indicated in the table at any time, in order to improve performances.