What is ‘Stress Box’?

‘Preventing failures and repair costs…’

hen a gearbox breaks down, it is essential to have the possibility to analyse the causes of this failure, to define which actions must be taken in order for this negative event not to occur again in the future. This is not possible without knowing the data concerning the physical values recorded before the accident occurred. For example: to successfully foresee the failure of a worm screw is of utmost importance from the point of view of the repair costs; the simple replacement of a bearing has an irrelevant cost if compared to the replacement of one or more damaged tools as a result of the failure of the bearing itself.

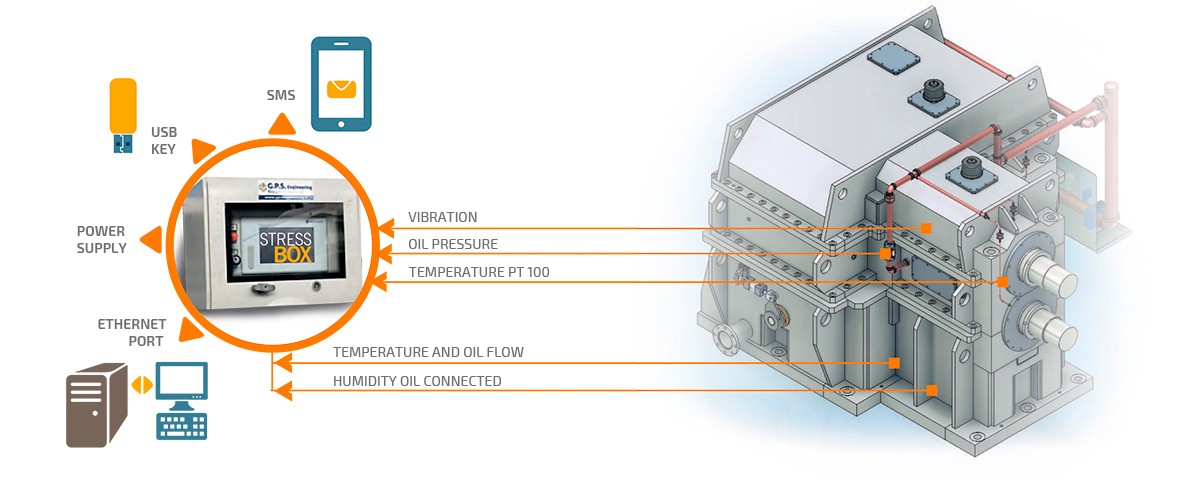

he “Stress Box” (conditions monitoring) records the detected instant values on a USB pen-drive and sends them by SMS and Ethernet, advising with text messages that the tolerance threshold of a part of the analysed machine has been exceeded, thus allowing the operator to intervene in advance on the mechanical system before it is too late and its failure occurs.

It can also operate, for a short while, in total absence of power supply, since one of the optional functions of the “Stress Box” includes sending an alarm SMS for “system blackout”.

‘Main functions’

Data recording on USB pen-drive (8Gb –csv fromat) up to 12 times/minute; ♦ Each input can be alarmed directly by the user; ♦ The text of the SMS shows the sensor and the value generating the alarm; ♦ Up to 7 probes Pt100, 7 analogue inputs (4-20 mA) and 8 digital inputs can be managed; ♦ Up to 8 digital outputs that may be configured by the user (for example, to activate a signal lamp or a siren when torque achieves the set-up value); ♦ An SMS can be sent in case of power supply blackout; ♦ An SMS can be sent weekly to detect the full operation of the “Stress Box”.

Share our Stress Box on social networks

Discuss the characteristics of our monitoring systems for special gearboxes, and of “Stress Box” in particular.